Waterjet Cutting Service

Categories :

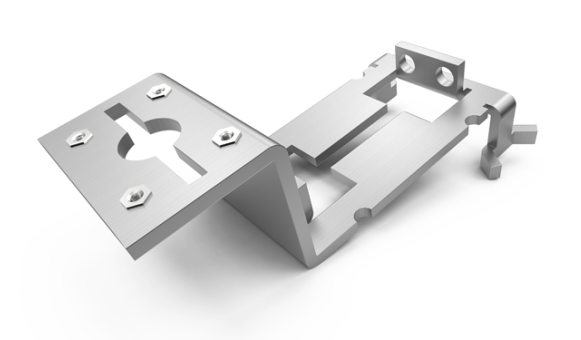

High Quality Waterjet Machined Parts

Waterjet cutting, also known as water jet or abrasive jet cutting, is one of Tiandiao's fabrication processes that directs a high-pressure jet of water and an abrasive substance to cut materials for industrial applications such as machine part manufacturing. Modern water jet cutters are controlled by CNC (Computer Numerical Control) systems running G-code to position the water jet nozzle and increase accuracy. Important benefits of water jet cutting with an abrasive substance include the ability to cut metals without increasing the material surface temperature and compromising internal structure of the material (no Heat Affected one, or HAZ); the ability to cut sharp corners, holes, and complex shapes with small inner radii; fast turnaround rates; and minimal material waste thanks to the precise cutting and the narrowness of the nozzle.

Our waterjet cutting services offer a cost-effective and on-demand solution for your manufacturing needs. Sheet metal fabrication services range from low-volume prototype to high-volume production runs. You can get an instant quote from a 3D CAD file or DXF file in our Instant Quoting Engine.

Waterjet Materials

Materials Available at Tiandiao:

| Aluminum |

Copper |

Steel |

| Aluminum 5052 |

Copper 101 |

Stainless Steel 301 |

| Aluminum 6061 |

Copper 260 (Brass) |

Stainless Steel 304 |

| Aluminum 7075 |

Copper C110 |

Stainless Steel 316/316L |

|

|

|

Steel, Low Carbon |

Available Finishes

Standard

Minimal post-processing or treatment on parts is done.

Bead Blast

The part surface is left with a smooth, matte appearance.

Anodized (Type II Or Type III)

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

Powder Coat

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

Chem Film (Chromate Conversion Coating)

Provides corrosion resistance and good conductivity properties. Can be used as a base for paint. Can leave surface yellow/gold.

Custom

Don’t see the finish you need? Submit an RFQ and we’ll look into a finishing process for you.

Blank Preparation

Waterjet can cut virtually any material, making it perfect for preparing material blanks to near-net shape.

Rapid Prototyping

The range of materials available, low cost per unit, and speed of production makes waterjet a great option for prototyping.

End-Use Production

Large format cutting, vast material options, and high throughput have made waterjet a favorable technology for end-use parts.

Advantages of Waterjet Cutting

Durability

Similar to CNC machining, sheet metal processes produce highly durable parts well-suited for both functional prototypes and end-use production.

Scalability

All sheet metal parts are built on-demand and with lower setup costs compared to CNC Machining. Depending on your needs, order as little as a single prototype up to 10,000 production parts.

Rapid Turnaround

Combining the latest cutting, bending and punching with automated technologies, Tiandiao provides instant sheet quotes and completed parts in as little 12 business days.

Material Selection

Choose from a variety of sheet metals across a wide range of strength, conductivity, weight, and corrosion-resistance.

Waterjet General Tolerances

| Description |

General Tolerance |

| Distance Dimensions |

For features of size (Length, width, diameter) and location (position, concentricity, symmetry) +/- 0.030” is typical. Material length and thickness may affect tolerances. |

| Thickness Dimension |

Thickness tolerances are determined by the material blank. |

| Minimum Recommend Part Size |

3.000" |

| Minimum Feature Size |

2X material thickness with a minimum of 0.125" |

| Kerf (slit size) |

Approximately 0.062" |

| Edge Condition |

Waterjet parts will have a vertical striation on the edges and may show a slight taper. |

Overview: What is Waterjet?

The Basics Of Waterjets

A waterjet cutter, also called a waterjet, is an industrial cutting device used for the fabrication of flat-cut parts. Using a nozzle to focus water into a high-pressure stream, a waterjet can be used to cut semi-soft materials like rubber, foam, or wood. Abrasive granular substances can be added to the jet in order to cut harder materials like aluminum and sheet metal.

How Waterjets Work

A waterjet is connected to a high-pressure pump, which pushes water through specialized tubing and then expels it from the nozzle at a focused volume and a velocity of up to 900 m/sec. The perfect ratio of velocity and volume is what allows the waterjet to maintain its unique high-pressure cutting stream.

In the case of abrasive water cutting, the abrasive substance (often garnet or aluminum oxide) is combined with the water in a chamber near the nozzle, and the mixture is then ejected in a thin water stream.

A waterjet is given great accuracy and repeatability by CNC technology, which is able to reliably manage the movement of the nozzle and water.

Why Use Waterjet Cutting For Your Parts?

Waterjet cutting does not warp or alter the structure of the material being cut, as a laser or more traditional cutting tool sometimes does. It is also capable of very fine and complicated shapes. Additionally, a waterjet’s precision cuts do not require sanding or grinding, and it produces no byproducts that might harm human operators or the environment — unlike laser cutting and plasma cutting. The water can also be recycled, reducing waste and cost while increasing energy efficiency.

CNC waterjet cutters can be used on almost any material, and are easily adjusted from pure water cutting to abrasive water cutting. This makes them an adaptable tool for many industries.

Why Choose Tiandiao for Waterjet Cutting?

|

|

|

Endless OptionsChoose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order. |

Easy to UseGet your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. |

Vetted NetworkWe are ISO 9001:2015 certified and AS9100D compliant. Only the top shops that apply to become Suppliers make it through our qualification process. |

Keyword:

Waterjet Cutting Service

Recommended Products

Leave a Message

Do You Have Any Intention To Cooperate?Please Leave Your Contact Information, And We Will Be Able To Contact You Immediately.