Stereolithography (SLA) 3D Printing Service

Categories :

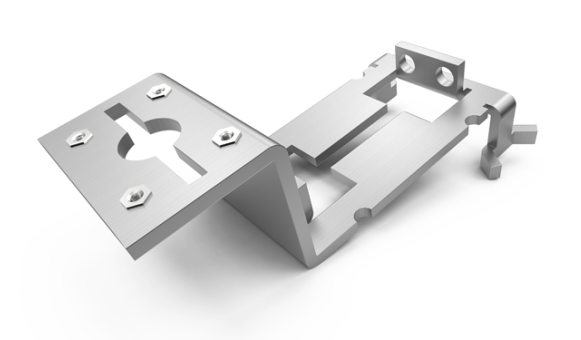

High-Resolution, Accurate Parts without Tooling

Stereolithography (SLA) is a powerful 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Tiandiao offers over 15 uniquely engineered SLA materials that can enable products to be brought to the market

Stereolithography Materials

SLA Materials Available at Tiandiao:

| Material Name |

Description |

Flexural Strength (MPa/KSI) |

Elongation at Break (%) |

HDT@0.46 MPa (°C) |

| Accura 25 |

White, PP-like |

58 MPa/KSI |

20% |

63 °C |

| Accura ClearVue |

Clear/Translucent, PC-like |

67 MPa/KSI |

7% |

46 °C |

| Somos Watershed Black |

Black/Dark-Grey, ABS-like |

69 MPa/KSI |

15% |

50 °C |

| Somos WaterShed XC 11122 |

Clear/Translucent, ABS-like |

69 MPa/KSI |

15% |

50 °C |

| Somos EvoLVe 128 |

White, ABS-like |

70 MPa/KSI |

11% |

52 °C |

| Accura Xtreme Grey |

Grey, ABS-like |

71 MPa/KSI |

22% |

62 °C |

| Somos NeXt |

White, PP-like |

71 MPa/KSI |

10% |

57 °C |

| Somos ProtoGen 18420 |

White, ABS-like |

71 MPa/KSI |

16% |

47 °C |

| Somos Taurus |

Dark Gray, ABS-like |

74 MPa/KSI |

24% |

62 °C |

| Accura ABS Black (SL 7820) |

Black (painted), ABS-like |

78 MPa/KSI |

13% |

51 °C |

| Accura Xtreme White 200 |

White, ABS-like |

79 MPa/KSI |

20% |

47 °C |

| Somos WaterClear Ultra 10122 |

Clear/Translucent, PC-like |

84 MPa/KSI |

7% |

47 °C |

| Accura 60 |

Clear/Translucent, PC-like |

101 MPa/KSI |

13% |

55 °C |

| Somos ProtoTherm 12120* |

Translucent Red, PC-like |

109 MPa/KSI |

4% |

126 °C |

| Accura 48HTR* |

Translucent Amber, PC-like |

118 MPa/KSI |

7% |

130 °C |

| Somos PerFORM* |

White, Ceramic-filled |

146 MPa/KSI |

1% |

268 °C |

| Accura Bluestone* |

Blue, Ceramic-filled |

154 MPa/KSI |

2% |

284 °C |

Available Finishes for SLA Parts

Matte (Standard)

Supported surfaces will be lightly sanded with 220 or 320 grit sandpaper, then media blasted for a uniform matte finish.

Natural

Supported surfaces will be lightly sanded with 220 or 320 grit sandpaper for improved surface quality. Sanding scratches will be visible on supported surfaces.

Strip and Ship

Supported areas may show small grid-like dots or surface blemishes as a result of support removal.

Quick Clear

Available for Accura ClearVue. Only supported surfaces are sanded. Parts will still have visible layering. High gloss clear coat is applied to enhance natural clarity.

Custom

Tiandiao provides additional SLA finishing options, including but not limited to sanding, polishing, painting, post thermal processing, and plating to meet your needs.

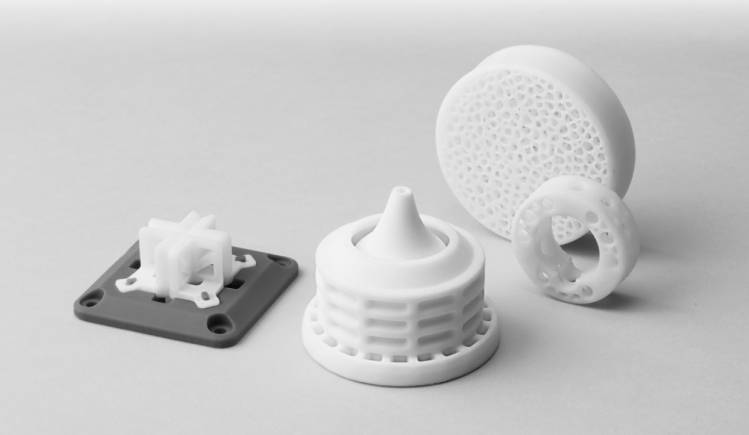

Applications of Stereolithography (SLA) 3D Printing

|

|

|

Concept ModelsThe speed, accuracy, and great surface finish of SLA parts lets product developers create physical snapshots of their designs through the iterative process. |

Rapid PrototypingSLA can be used to create fully-functional prototypes, with materials that can simulate polypropylene, polycarbonate, ABS, and rigid composites. |

Direct Digital ManufacturingThe high accuracy and consistency of SLA makes it an ideal way to build large quantities of discrete or customized parts. |

Benefits of SLA 3D Printing

SLA is a go-to choice for 3D printed models requiring accurate features and a smooth surface finish. Tiandiao offers standard and high-resolution options for fine detail parts and can print larger parts and products, offering up to a 29" inch build area. With the ability to produce complex features with good mechanical properties, SLA 3D prints are often used for final fit checks before moving to injection molding services.

In addition, Tiandiao's manufacturing partner network allows us to offer a wider variety of materials than other 3D printing companies - we offer a wide range of Accura and Somos brand materials.

· Outstanding surface finish and post processing options

· Tight tolerances and high detail precision.

· Complex shapes with a high degree of precision.

· High selection of engineered material

| Description |

Standard Resolution |

High Resolution |

| General Tolerances |

XY plane: +/- 0.005" for the first inch, plus +/- 0.002" for every inch thereafter. |

XY plane: +/- 0.005" for the first inch, plus +/- 0.002" for every inch thereafter. |

| Build Envelope |

29” x 25” x 21” |

10” x 10” x 10” |

| Layer Height |

0.004" |

0.002" |

| Minimum Feature Size |

0.020" (Recommended 0.030") |

0.020" |

Overview: What is Stereolithography (SLA) 3D printing?

How Stereolithography Works

SLA is an additive manufacturing process that uses ultraviolet (UV) light on a vat of liquid photopolymer resin to selectively solidify part features, building the part layer by layer. The UV light continues this process through the entire vat of resin, selectively curing and solidifying the resin to match the design of the CAD file. Structural supports are created during the pre-build setup process and manually removed after the print is completed. The parts are then washed in a solvent solution to remove uncured resin, and then receive a final post-cure in a UV light oven.

SLA offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings, often acting as a stand-in for injection molded parts.

Applications of Stereolithography

With a broad range of suitable materials and a rapid turnaround for even complex net-shapes, stereolithography is an ideal tool for a broad range of manufacturing sectors. It is primarily used in auto-engineering, as it enables the cost-effective generation of intricate parts with various surface finishes and fine detailing. Parts can be embossed or engraved, with matte, natural, and myriad other finishes available depending on the manufacturing requirements. While its primary success has been in rapid prototyping and design assistance for the automotive sector, stereolithography is rapidly being adopted at scale in various mechanical modeling sectors.

Why Choose Tiandiao for 3D Printing?

|

|

|

Endless OptionsChoose from thousands of possible combinations of materials, finishes, tolerances, markings, and certifications for your order. |

Easy to UseGet your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. |

Guaranteed QualityWe conform with ISO 9001:2015 |

Keyword:

Stereolithography (SLA) 3D Printing Service

Recommended Products

Leave a Message

Do You Have Any Intention To Cooperate?Please Leave Your Contact Information, And We Will Be Able To Contact You Immediately.