Sheet Metal Fabrication Services

Categories :

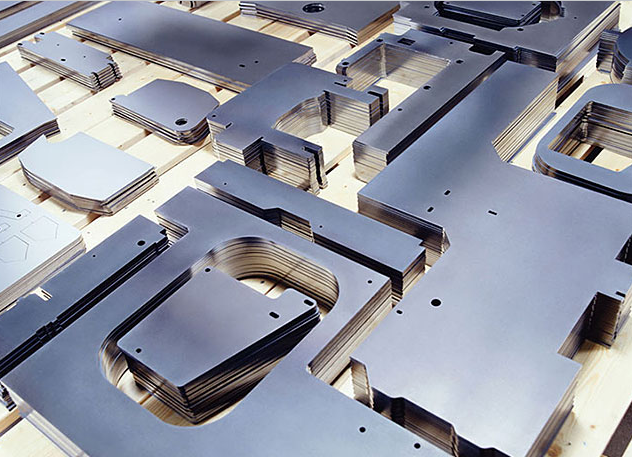

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets.

Tiandiao’s sheet metal fabrication services provide a fast and cost-effective solution for any parts that need to be made from 3D CAD files or engineering drawings. Tiandiao offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel, as well as assembly services like installing PEM inserts, welding, and finishing services. With a network of domestic and overseas fabricators, Tiandiao can supply any quantity of parts from low-volume, high-mix prototypes to high-volume production runs. Tiandiao offers competitive sheet metal prices for low volume prototypes and cost savings for high volume production runs.

Sheet Metal Operations Available at Tiandiao

|

|

|

Laser Cutting ServiceHigh-quality Laser Cut Parts in Days Not Weeks |

Waterjet Cutting ServiceInstant Quotes and Cost-effective, On-demand Fabrication |

Plasma Cutting ServiceCustom Plasma Cutting for Prototyping and Production Part Fabrication |

| Feature |

Description |

| Blank Size |

10’ x 20’ (3.05 m x 6.10 m). We accommodate larger part volumes upon request. |

| Standard Lead Time |

3 business days |

| Sheet Thickness |

0.024” - 0.250” typical. We accommodate thicker or thinner gauges upon request. |

| General Tolerances |

For single planes or flat parts, +/- 0.005” on edge to edge, edge to hole, and hole to hole features; +/- 0.010” on bend to edge/hole features. For multi-planed bent parts, +/- 0.030” for hole to hole/edge, edge to edge, and over-formed parts; +/- 1 degree for bend angles. |

| Braking (Hydraulic) |

10’ length, fingers from 3” - 6” |

| Braking (Magnetic) |

6 tons of magnetic pull across the entire beam, 5/8″ minimum reverse bend |

| Punching |

2″ diameter hole capacity, or larger upon request |

| Welding |

Welded edges and seams, weldments, and assemblies |

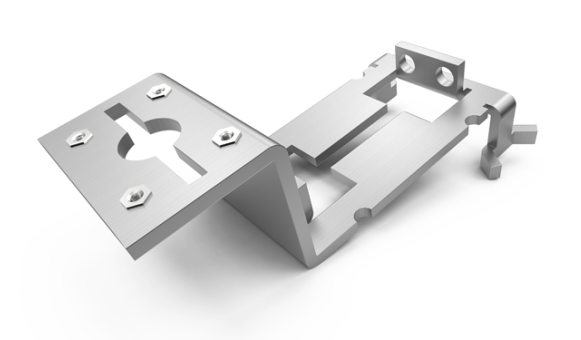

How Tiandiao Sheet Metal Fabrication Works

Tiandiao's metal fabrication services utilize the top sheet metal fabricators. Sheet metal fabricators first convert CAD and drawing data into machine code. A laser cutting, waterjet, or plasma cutting machine will then precisely remove sheet metal material. The raw material is formed into angular bends and features using brakes, punches, and dies. If any assembly or post-processing is required, our sheet metal manufacturers will weld, add inserts, or finish the part.

The efficiency and high precision of metal fabrication, coupled with Tiandiao’s variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application. Sheet metal applications include aerospace, defense, automotive, energy, industrial, medical, dental, and consumer products.

Sheet Metal Materials Available at Tiandiao

Aluminum

Aluminum 6061: A heat-treatable aluminum sheet metal with medium to high strength, used for a variety of applications including furniture, boats, and automotive.

Aluminum 5052: A lightweight, corrosion-resistant aluminum with good forming and welding characteristics; it is the most commonly used sheet metal fabrication material.

Copper

Copper 101: A highly conductive, 99.99% pure sheet metal copper often used in specialty electrical applications.

Copper C110: A low-cost, multipurpose copper often used in electrical sheet metal applications.

Brass

Copper 260 (Brass): A highly formable brass often used in high heat components and decorative home hardware.

Stainless Steel

Stainless steel 301: A high-strength stainless steel for sheet metal, used for aircraft, automotive, and train structural components, appliances, and utensils.

Stainless steel 304: The most common stainless steel for sheet metal fabrication applications with increased corrosion resistance over 301 and industrial applications like food processing equipment, railing and trim, and more.

Stainless steel 316/316L: A stainless steel with increased corrosion resistance over 301 and 304, which makes it ideal for marine, medical, chemical, and chemical processing applications.

Steel

Steel 1018 (Low Carbon): A highly formable and weldable steel due to its ductility and high heat-transferability. This material is typically cheaper than aluminum but is of lower strength and is susceptible to corrosion.

Custom

Additional alloys and tempers are available upon request. We can source to your project specifications. Review more information about our materials here .

Available Sheet Metal Finishes

A variety of material finishes are available for an instant quote. If you do not see the material finish combination you are looking for, please submit a quote for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required.

Available Sheet Metal Finishes

Standard

Minimal post-processing or treatment on parts is done.

Bead Blast

The part surface is left with a smooth, matte appearance.

Anodize (Type II Or Type III)

Type II (MIL-A-8625, Type II) creates a corrosion-resistant finish. Sheet metal parts can be anodized in different colors—clear, black, red, and gold are most common—and are usually associated with aluminum. Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

Chem Film (Chromate Conversion Coating)

This sheet metal finish provides corrosion resistance and good conductivity properties. Chem film can be used as a base for paint and can leave surfaces yellow or gold. Adds very little thickness, about 0.00001”-0.00004.” Chem film will conform to MIL-DTL-5541, TYPE I/II.

Powder Coat

This is a process where powdered paint is sprayed onto a part that is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

Electroless Nickel Plating

Provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. The finished part will be brighter. Thickness starts at .0001” and this finish conforms to MIL-C-26074.

Gold Plating

Gold Plating provides good corrosion and tarnish resistance with excellent solderability. Default application specification is MIL-G-45204 & ASTM B488, CLASS 00, 0, OR 1 (Thickness 0.00002" - 0.00005").

Silver Plating

Silver offers high solderability and electrical conductivity but is susceptible to tarnish on sheet metal parts. Conforms to AMS QQ-S-365D. Thickness is about 0.00002”- 0.0003.”

Sheet Metal Design Guidelines

| Feature |

Description (MT = Material Thickness) |

| Minimum Bend |

1X MT |

| Minimum Hole to Edge Distance |

2X MT |

| Minimum Hole to Hole Distance |

6X MT |

| Minimum Bend Edge to Hole Distance |

6X MT |

| Minimum Feature to Countersink Distance |

8X MT |

| Minimum Countersink Depth |

0.6X MT |

| Relief Cuts |

1X MT |

| Corner Fillets |

0.5X MT |

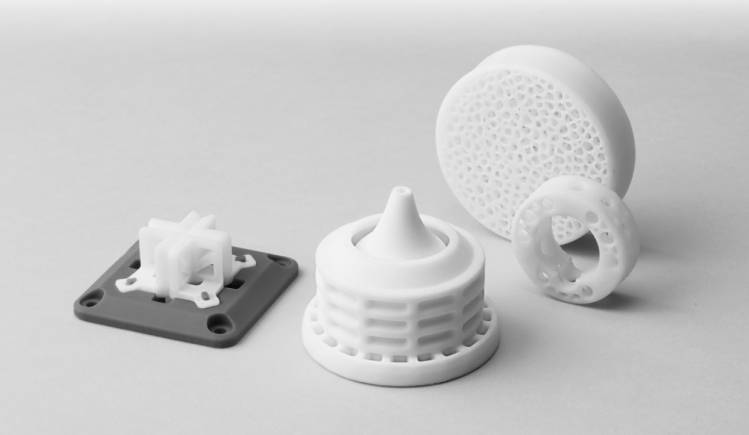

Applications and Advantages of Sheet Metal Fabrication

|

|

|

Rapid ToolingSheet metal can be quickly cut into 2D profile shapes and formed out of a variety of high-strength materials, making it perfect for rapid tooling. |

Rapid PrototypingWith lead times starting at 3 days, no minimum order volumes, and low-per-unit costs, rapid sheet metal is a great option for prototyping. |

End-Use ProductionPer-unit pricing lowers significantly in production volumes. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method. |

Why Use Tiandiao's Sheet Metal Fabrication Services?

|

|

|

Endless OptionsChoose from thousands of possible combinations of sheet metal materials, finishes, tolerances, markings, and certifications for your order. |

Easy to UseGet your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. |

Guaranteed QualityWe conform with ISO 9001:2015. |

Keyword:

Sheet Metal Fabrication Services

Recommended Products

Leave a Message

Do You Have Any Intention To Cooperate?Please Leave Your Contact Information, And We Will Be Able To Contact You Immediately.