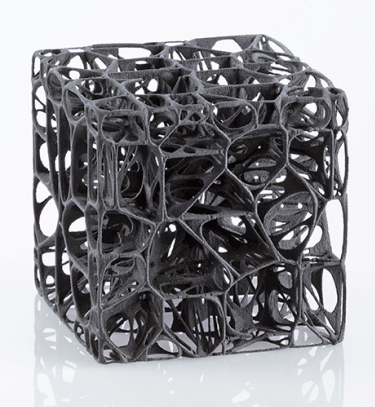

Selective Laser Sintering (SLS) 3D Printing Service

Categories :

SLS 3D Printing Service

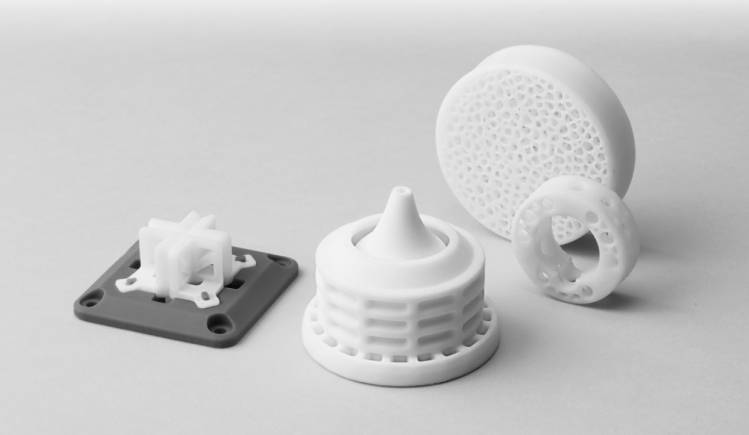

Selective laser sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. SLS is one of the most inexpensive options for industrial 3D printing services because it can build parts in bulk without support structure requirements.

An additive manufacturing layer technology, selective laser sintering involves the use of a high-power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the selective laser sintering process is repeated until the part is completed.

SLS Materials

Selective Laser Sintering 3D Printing Materials

| Material Name |

Other Common Names |

Shore Hardness |

Elongation at Break (%) |

Impact Strength, Notched (kJ/m²) |

| Nylon 12 |

Durable plastic, PA12, PA 2200 |

75D |

18% |

4.8 kJ/m² |

| Nylon 12, Glass-filled (GF) |

Stiff plastic, PA12 GF, PA 3200 GF |

80D |

9% |

4.2 kJ/m² |

| Nylon 11 EX |

Ductile plastic, PA11, Rilsan® Invent Natural |

77D |

45% |

No break |

| Nylon 12, Carbon-Filled (CF) |

High-performance plastic, carbon-filled PA12, PA 602-CF, carbonmide |

N/A |

4% |

5.3 kJ/m² |

| Nylon 12, Aluminum-Filled (AF) |

Metallic gray plastic, aluminum-filled PA12, alumide |

76D |

3% |

4.6 kJ/m² |

| Nylon 12, Mineral-Filled (HST) |

Heat-resistant plastic, mineral fiber-reinforced PA12, PA 620-MF |

75D |

3-5% |

N/A |

SLS Finishes at Tiandiao

Standard

SLS parts are de-powdered with a sandblasting process and manual powder removal. Internal holes may be drilled to size if accessible. The finish is white matte (fine sugar-cube).

Color Dyed

Color options of dye black, blue, green, red, or yellow. Batch to batch consistency may vary slightly with black being the most consistent. Dye penetrates ~0.010" deep.

Vapor Smoothing

An automated post-processing technology (AMT PostPro3D) that achieves a high-quality surface finish. Vapor smoothing brings most surfaces from a matte to a semi-gloss. Vapor smoothing also seals the surface, enhances mechanical properties, and provides a consistent cosmetic finish for production. Vapor smoothed parts can be dyed.

Media Tumbled

Standard finish with the addition of abrasive media tumbling. These parts will have reduced grow lines and sharp edges may be softened by the tumbling process. The parts are left with an eggshell finish.

Nickel Plating

Standard finish with a secondary copper + nickel plating processes adding 0.004"-0.006" nickel coating. Nickel plating adds durability, stiffness, and wear resistance but is not considered cosmetic. Finish is rough nickel.

Additional Finishes

Tiandiao provides additional SLS finishing and customization options upon request.

Vapor Smoothing SLS 3D Printed Parts

Tiandiao can vapor smooth 3D printed parts to achieve an exceptional surface finish. Vapor smoothing, performed through AMT PostPro3D's technology, is a batch-based automated smoothing process that achieves a high-quality surface. Combined with the low costs SLS, this surface finish can make parts competitive with injection molding from both form and function. Vapor smoothing creates a uniform, sealed surface with a semi-gloss appearance. SLS parts can be color-dyed. The enhanced surface also increases the overall performance of 3D printed parts including ultimate tensile strength, yield at flex, and percent elongation to break. Vapor smoothing can be applied to HP Multi Jet Fusion, selective laser sintering, and fused deposition modeling parts for both rigid plastics and elastomers.

Applications for Selective Laser Sintering

|

|

|

Concept ModelsThe speed and versatility of SLS lets product developers create physical snapshots of their designs through the iterative process. |

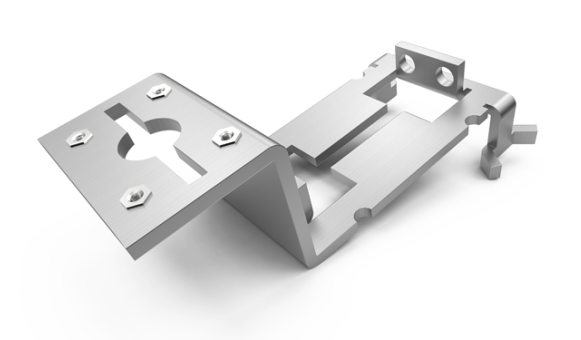

Rapid PrototypingSLS can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies. |

Direct Digital ManufacturingThe high accuracy and consistency of SLS makes it an ideal way to build large quantities of discrete or customized parts. |

Advantages of SLS

Durability

Nylon is a durable material with great impact strength, medium flexibility, and high resistance to environmental factors.

Rapid Turnaround

Parts can typically be shipped in 3-4 days, allowing for faster design iterations and speed to market.

Parts Production

SLS is capable of producing end-use parts on-demand, increasing throughput.

Complex Geometry

Geometries can be built more easily due to the 3D printing process, adding complexity without additional cost.

Scalability

SLS can produce a single part or component as easily as dozens of production pieces.

Precision

We utilize state-of-the-art SLS technology to achieve tolerances of +/- 0.005” or +/- 0.002” per inch, whichever is greater. Refer to our Manufacturing Standards for more details.

SLS General Tolerances

| Description |

Tolerance Notes |

| General Tolerances |

+/- 0.005” for the first inch is typical, with an additional +/- 0.002” for each subsequent inch. |

| Build Area |

Build area up to 13" x 13" x 20". Glass-filled parts can extend up to 26" x 15" x 23". |

| Minimum Feature Size |

0.030" or greater. |

| Standard Layer Thickness |

0.0045 |

Overview: What is SLS?

The Basics Of Selective Laser Sintering

Selective laser sintering (SLS) is a powder bed 3D printing technology that produces highly accurate and durable parts suitable for direct use in end-use, low-volume production. SLS is a relatively new 3D printing process, often considered similar to direct metal laser sintering (DMLS), a popular metal 3D printing technology. Both processes use a laser to precisely fuse a powder bed to create a part from a 3D CAD file. SLS uses nylon or polyamide powder particles, while DMLS uses metal particles. SLS is extremely common for prototyping and low-volume production.

The Benefits Of Working With Tiandiao For Selective Laser Sintering

Tiandiao can help you find the ideal supplier for your specific SLS needs. Our factory has a wide range of dedicated, quick-turn SLS partners offering high-quality finishing and material capabilities, and various sintering systems. Finishing options include color dyeing, sanding, painting, and plating. We cater to both low-volume prototyping and high-volume production.

Benefits of SLS 3D Printing Process

Selective laser sintering can produce parts from various materials, including plastic, metal, ceramic, or glass powder, making it a popular machining process. Since SLS doesn't require support structures like most other 3D printing technologies, parts can be made in larger quantities with reduced labor and material costs. Furthermore, the absence of support structures minimizes the risk of damage to complex internal geometries often produced by 3D manufacturing.

SLS is useful for rapid prototyping and low-volume production of functional end-use parts. Nylon, in particular, is a durable material with high impact strength, medium flexibility, and high resistance to environmental factors. This combination of complexity, design flexibility, material diversity, rapid turnaround, and durability makes SLS increasingly popular across various industries.

Why Choose Tiandiao for SLS?

|

|

|

Endless OptionsChoose from thousands of possible combinations of materials, finishes, tolerances, markings, and certifications for your order. |

Easy to UseGet your parts delivered directly, eliminating the hassle of sourcing, project management, logistics, and shipping. |

Guaranteed QualityWe are ISO 9001:2015 compliant. |

Keyword:

Selective Laser Sintering (SLS) 3D Printing Service

Recommended Products

Leave a Message

Do You Have Any Intention To Cooperate?Please Leave Your Contact Information, And We Will Be Able To Contact You Immediately.