Plasma Cutting Service

Categories :

Custom Plasma Cutting Service

Tiandiao's custom plasma cutting service offers a cost-effective on-demand fabrication solution for your sheet metal needs. Thanks to our Instant Quoting Engine, we can provide instant pricing for any size fabrication run from low-volume prototyping to high-volume production.

You can send us a 3D CAD file for an instant quote.

Available Types Of Plasma Cutters

2-Axis

This is the most common and conventional form of a plasma cutter and operates like any traditional CNC sheet metal fabrication tool, producing flat profiles with straight edges. These plasma cutters are best for cutting large parts from thick material quickly and are more cost-efficient than CNC laser cutters for the same work.

3-Axis

This type of CNC plasma cutter adds in an additional axis of rotation which allows the cutting tool to tilt and cut edges at an angle. This is extremely useful for cutting chamfers, countersunk holes or angled edges as part of weld preparation, which saves on secondary operations such as grinding or machining helping reduce overall cost.

Applications of Plasma Cutting

Blank Preparation

Plasma cutting can build near net shapes of conductive metals, making it perfect for material preparation.

Rapid Prototyping

The range of materials available, low cost per unit, and speed of production makes waterjet a great option for prototyping.

End-Use Production

Large format cutting, vast material options, and high throughput have made plasma cutting a favorable technology for end-use parts.

Advantages of Plasma Cutting

Durability

Similar to CNC machining, sheet metal processes produce highly durable parts well-suited for both functional prototypes and end-use production.

Scalability

All sheet metal parts are built on-demand and with lower setup costs compared to CNC Machining. Depending on your needs, order as little as a single prototype up to 10,000 production parts.

Material Selection

Choose from a variety of sheet metals across a wide range of strength, conductivity, weight, and corrosion resistance.

Rapid Turnaround

Combining the latest cutting, bending, and punching with automated technologies, Tiandiao provides instant sheet quotes and completed parts often within a week.

Plasma Cutting General Tolerances

| Description |

General Tolerance |

| Distance Dimensions |

For features of size (Length, width, diameter) and location (position, concentricity, symmetry) + 0.125", -0.000 is typical. Material length and thickness may affect tolerances. |

| Thickness Dimension |

Thickness tolerances are determined by the material blank. |

| Minimum Recommend Part Size |

1.000" |

| Minimum Feature Size |

2X material thickness with a minimum of 1.000" |

| Kerf (slit size) |

Approximately 0.50" |

| Edge Condition |

Plasma edge will have vertical striations and be tapered. Upper edges may have a rounded area with top splatter. |

An Overview of Plasma Cutting

The Basics Of Plasma Cutters

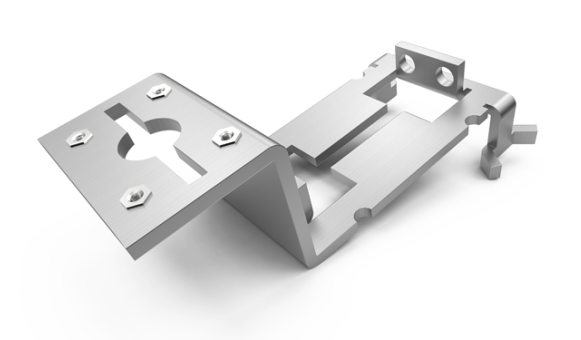

Plasma cutting uses an accelerated jet of hot plasma to cut through electrically conductive materials. Plasma cutters are the fastest way to cut through gauge material up to 6" thick and are more cost-efficient to run than high-powered CNC laser cutters. Plasma cutters do their best work on large sheet metal parts, versus CNC laser cutters which are better at more detailed work and creating holes — something plasma cutters struggle with.

How Plasma Cutters Work

When energy and heat are applied to a gas, the molecules travel faster and collide more violently, turning the gas into a plasma. Using compressed air or other inert gas, the plasma is accelerated out of the cutting nozzle toward the workpiece where it completes an electrical arc with the conductive workpiece. Similar to Electrical Discharge Machines, plasma cutters use electricity to melt and cut the workpiece.

The Benefits Of Working With Tiandiao For Plasma Cutting

Tiandiao's quick turn custom plasma cutting services offer a cost-effective and on-demand fabrication solution for your sheet metal needs. Thanks to our Instant Quoting Engine, we can provide instant pricing for any size fabrication run from low-volume prototyping to high-volume production.

Why Use Plasma Cutting For Your Parts?

Plasma cutters are a good all-around sheet metal fabrication tools, though they lack the material cutting diversity of waterjet cutters and don’t have the precision of laser cutters. For larger sheet metal parts, plasma cutters are more cost-efficient than CNC laser cutters and can cut thicker materials easily. Plus, they are easy to operate and can cut at high speeds while maintaining precision.

Sheet metal offers a cost-effective way to fabricate product device panels, boxes and cases for a variety of applications. We build enclosures of all styles, including rackmounts, “U” and “L” shapes, as well as consoles and consolets.

Why Choose Tiandiao for Plasma Cutting?

|

|

|

Endless OptionsChoose from thousands of possible combinations of materials, finishes, tolerances, markings, and certifications for your order. |

Easy to UseGet your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. |

Guaranteed QualityWe conform with ISO 9001:2015 |

Keyword:

Plasma Cutting Service

Recommended Products

Leave a Message

Do You Have Any Intention To Cooperate?Please Leave Your Contact Information, And We Will Be Able To Contact You Immediately.