Laser Cutting Service

Categories :

High Quality Laser Cutting

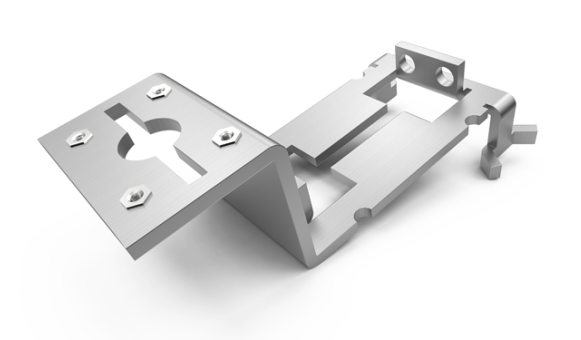

Laser cutting is one of Tiandiao's sheet metal profiling processes that directs a high-power laser through optics to cut materials for industrial applications. Laser cutting is both more precise and less energy-consuming than plasma cutting, but has an upper threshold on the thickness of the material being cut. Tiandiao's Manufacturing offers both fiber and CO2 lasers that can cut many materials including mild steel, stainless steel, aluminum, copper, brass, and exotic alloys. CO2 (carbon dioxide) laser excels at cutting, engraving, and boring metals, while fiber laser is a good option for thicker materials. For sheet and plate metal thicker than 4 inches, see our waterjet cutting services.

Our custom laser cutting service offers a cost-effective and on-demand solution for your manufacturing needs. Sheet metal fabrication services range from low-volume prototype to high-volume production runs.

You can send us a 3D CAD file for an instant quote.

Types Of Laser Cutters Available From Tiandiao

C02 lasers

The most common laser types because of their relatively high energy efficiency and high power output ratio. Best suited for cutting, boring, and engraving.

Nd lasers

Have a high energy, but low repetition efficiency.

Nd:Yag lasers

Higher powered for cutting thicker materials but more expensive to operate.

Both Nd/Nd:Yag lasers are used for boring and welding. Nd:Yag lasers can also be used for engraving.

Laser Cutting Materials

Materials Available at Tiandiao:

| Aluminum |

Copper |

Steel |

| Aluminum 5052 |

Copper 101 |

Stainless Steel 301 |

| Copper C110 |

Stainless Steel 304 |

|

| Copper 260 (Brass) |

Stainless Steel 316/316L |

|

| Steel, Low Carbon |

Available Finishes

Standard

Minimal post-processing or treatment on parts is done.

Bead Blast

The part surface is left with a smooth, matte appearance.

Anodized (Type II or Type III)

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

Powder Coat

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

Chem Film (Chromate Conversion Coating)

Provides corrosion resistance and good conductivity properties. Can be used as a base for paint. Can leave surface yellow/gold.

Custom

Don’t see the finish you need? Submit an RFQ and we’ll look into a finishing process for you.

|

|

|

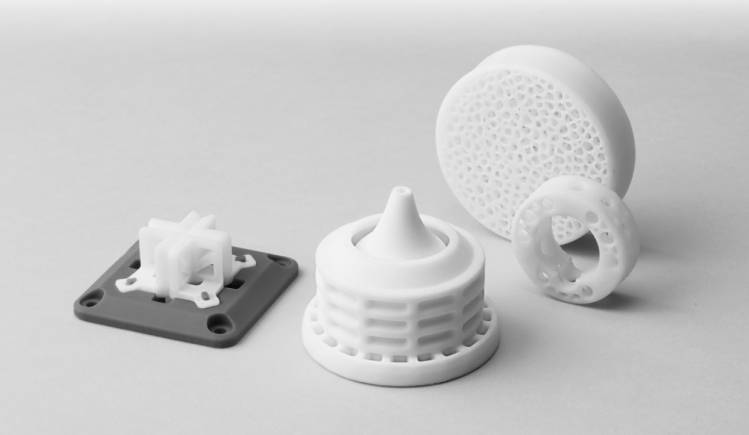

| Blank Preparation Lasers can cut many materials with high precision, making it perfect for preparing flat patterns or material blanks. |

Rapid Prototyping The range of materials available, low cost per unit, and speed of production makes laser cutting a great option for prototyping. |

End-Use Production Large format cutting, vast material options, and high throughput have made laser cutting a favorable technology for end-use parts. |

Advantages of Laser Cutting

Durability

Similar to CNC machining, sheet metal processes produce highly durable parts well-suited for both functional prototypes and end-use production.

Scalability

All sheet metal parts are built on-demand and with lower setup costs compared to CNC Machining. Depending on your needs, order as little as a single prototype up to 10,000 production parts.

Material Selection

Choose from a variety of sheet metals across a wide range of strength, conductivity, weight, and corrosion resistance.

Rapid Turnaround

Combining the latest cutting, bending and punching with automated technologies, Tiandiao provides instant sheet quotes and completed parts in as little as 12 business days.

Material Selection

Choose from a variety of sheet metals across a wide range of strength, conductivity, weight, and corrosion-resistance.

Laser Cut Metal General Tolerances

| Description | General Tolerance |

| Distance Dimensions | For features of size (Length, width, diameter) and location (position, concentricity, symmetry) +/- 0.010” is typical. Material length and thickness may affect tolerances. |

| Thickness Dimension | Thickness tolerances are determined by the material blank. |

| Minimum Recommend Part Size | 1.000" |

| Minimum Feature Size | 2X material thickness with a minimum of 0.062" |

| Kerf (slit size) | Approximately 0.020" |

| Edge Condition | Laser cut parts will have a matte, vertical striation on the edges. |

An Overview of Laser Cutting

The Basics Of Laser Cutters

Laser cutters are CNC machines that use a thin, high-powered laser beam to cut materials. The process is most often used in industrial manufacturing. Laser cutters are commonly used for quality welding and to cut industrial sheet metal, but laser cutters can also be used for other materials from composites to rubber, glass, wood, and aluminum.

How Laser Cutters Work

Laser focusing optics are used to direct electrical energy into a high-density light beam, and CNC is used to manage either the workpiece or the laser beam. The material processed by the laser cutter is then melted, burned, vaporized, or blown away by a jet of oxygen or nitrogen.

Why Use Laser Cutting For Your Parts?

Laser cutting offers several advantages over traditional mechanical cutting or CNC machining processes, including quicker production, decreased contamination of the workpiece, and reduced chance of warping. Laser cutting produces clean cuts and has a small chance of operator error making them great for fast prototyping.

Tiandiao's custom laser cutting services offer a cost-effective on-demand solution for your sheet metal fabrication needs, including the material, details, and size of the project. From fast, low-volume prototypes to high-quality, high-volume production runs, Our factory has the ideal machines for the job.

Why Tiandiao ?

|

|

|

Endless OptionsChoose from thousands of possible combinations of materials, finishes, tolerances, markings, and certifications for your order. |

Easy to UseGet your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. |

Guaranteed QualityWe conform with ISO 9001:2015 |

Keyword:

Laser Cutting Service

Recommended Products

Leave a Message

Do You Have Any Intention To Cooperate?Please Leave Your Contact Information, And We Will Be Able To Contact You Immediately.