Injection Molding Service

Categories :

What Is Injection Molding?

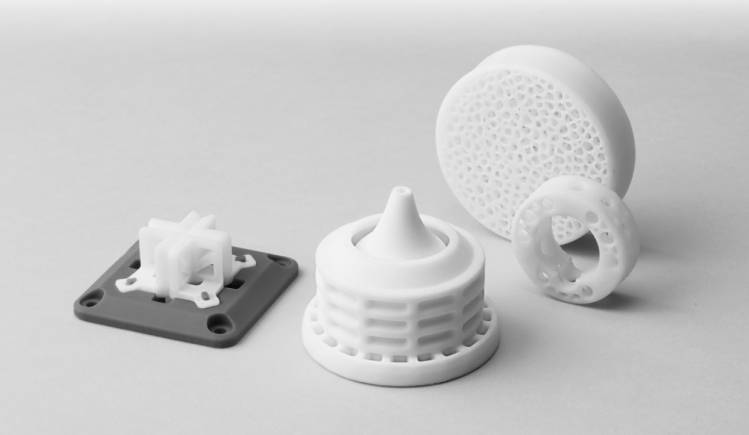

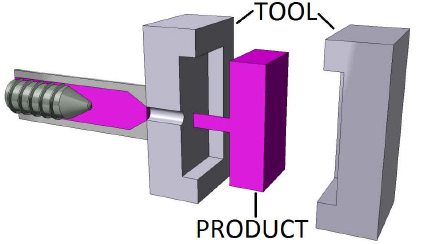

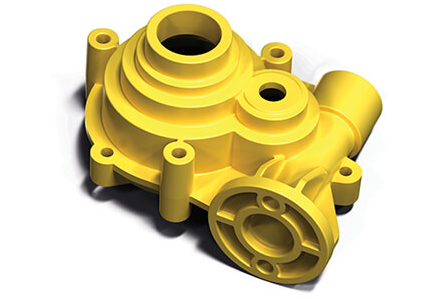

Injection molding, also known as injection moulding, is the most cost-effective way to make a plastic part at scale. The process involves injecting molten plastic into a mold tool, then ejecting the solidified part. This process quickly repeats hundreds or thousands of times, amortizing the cost of the mold tool and driving down the cost of each unit to a few dollars or less. Since injection molding uses the same mold tool for each part, the process offers consistent quality across every part. Injection molding also has the highest variety of materials, colors, cosmetics, polishes, and surface textures when compared to CNC machining or even 3D printing.

Tiandiao injection molding is a highly customized service providing on-demand prototype and production molding. We take a customer-first approach which means our expert manufacturing team will reach out the right injection molding to mold the parts the way you need them—without design compromises—at the right price point. We offer expert consultation on each injection mold quote and project managers on every order to move your parts from design to production. Our team has experience in every industry, especially medical injection molding.

Tiandiao Injection Molding Capabilities

| Service |

Details |

| Lead Time |

Starts at 10 business days, including 24-hour quote responses with design-for-manufacturing (DFM) feedback |

| Production Options |

Domestic and international |

| Materials |

Most plastics, including custom sourcing and matching; see materials list below |

| Machines Available |

Single, multi-cavity, and family molds; 50 to 1,100+ press tonnage; side actions including hand-loaded cores |

| Inspection and Certification Options |

Includes FAI and PPAP. ISO 9001, AS9100, ISO 13485, UL, ITAR, and ISO 7 and 8 Medical Clean Room molding. |

| Tool Ownership |

Customer-owned with mold maintenance |

| Mold Cavity Tolerances |

+/- 0.005" when machining the mold and an additional +/- 0.002" per inch when calculating for shrink rate |

| Part to Part Repeatability |

+/- 0.004" or less |

| Critical Feature Tolerances |

Tighter tolerances can be requested and may increase the cost of tooling because of additional sampling and grooming. Tiandiao will mill to a steel-safe condition on critical features. |

| Available Mold Types |

Steel and aluminum; Production grades range from Class 105, a prototype mold, to Class 101, an extremely high production mold. Tiandiao typically produces Class 104, 103, and 102 tools. |

Tiandiao Injection Molding Mold Classes

| Class 105 |

Class 104 |

Class 103 |

Class 102 |

Class 101 |

| Under 500 cycles. Prototype only. This mold will be constructed in the least expensive manner possible to produce a very limited quantity of prototype parts. Also known as a Class V tool. Example: a one-and-done market test of 100 molded units. |

Under 100,000 cycles. Low production mold. Use only for limited production preferably with non-abrasive materials. Low to moderate price range. Also known as a Class IV tool. Example: Aluminum or MUD tooling, SPI B-3 finish, hand-loaded cores, and limited re-runs. |

Under 500,000 cycles. Medium production mold. This is a very popular mold for low to medium production needs. Most common price range. Also known as a Class III tool. Example: Aluminum or steel tooling, automated lifts or slides, multiple re-runs with batches between 1,000-5,000 units. |

Medium to high production, good for abrasive materials and/or parts requiring close tolerance. This is a high-quality, fairly high-priced mold. Also known as a Class II tool. Example: Steel tooling with an SPI A-2 finish, automated slides, scheduled production cycles. |

Over 1,000,000 cycles. Built for extremely high production. This is the highest-priced mold and is made with only the highest quality materials. Also known as a Class I tool. Example: Multiple-cavity steel tooling with full automation and overnight production work centers for dedicated part manufacturing. |

Additional Molding Options Available at Tiandiao

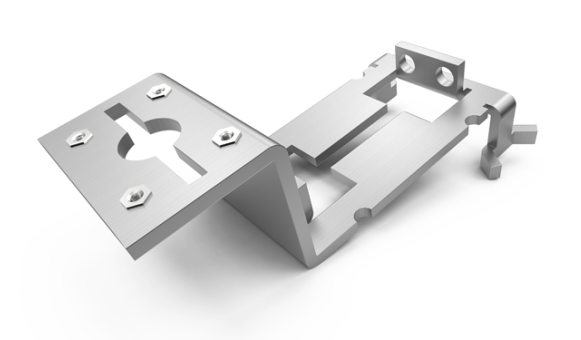

Insert Molding Service

Make Strong, Functional Prototypes and Production Parts With Insert Molding

Overmolding Service

High Quality Process for Pilot Runs, Low-Volume Production, and Bridge Tooling

How Custom Plastic Molding Works at Tiandiao

The process of plastic injection molding requires an injection molding machine, raw plastic material, and a machined mold. The raw plastic material is first melted in the injection unit and is then injected into the mold—most often machined from steel or aluminum—where it cools and solidifies into the final plastic part.

At Tiandiao, we first review your injection molding quote, then consult with you to ensure your specifications, lead time, and price fit your project needs. We then use your 3D part data to CNC machine a high-quality injection mold. Once the mold is created, Tiandiao sends ten part samples (T1) for approval. Once the mold is refined and approved, Tiandiao begins production. Tiandiao molds a variety of products and parts from the smallest medical insert up to large automotive, aerospace, and defense parts.

| Rigid And Flexible Resins | ||

| ABS | Acrylonitrile Butadiene Styrene |

PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene |

PMMA | Polymethyl Methacrylate, Acrylic |

| ASA | Acrylonitrile Styrene Acrylate |

PC-PBT | Polycarbonate-Polybutylene Terephthalate, Xenoy |

POM | Acetal Polyoxymethylene, Delrin |

| CA | Cellulose Acetate |

PC-PET | Polycarbonate-Polyethylene Terephthalate |

PP | Polypropylene |

| COPO | Copolyester |

PCT | Polycyclohexylenedimethylene Terephthalate |

PPA | Polyphthalamide |

| HDPE | High-Density Polyethylene |

PE | Polyethylene |

PPS | Polyphenylene Sulfide, Ryton |

| LCP | Liquid Crystal Polymer |

PE-PP | Polyethylene-Polypropylene |

PS | Polystyrene |

| LDPE | Low-Density Polyethylene |

PE-PS | Polyethylene-Polystyrene |

PS-PPE | Polystyrene-Polyphenyl Ethers, Noryl |

| PA 6 | Polyamide 6, Nylon 6 |

PEBA | Polyether Block Amide |

PSU | Polysulfone, Udel |

| PA 6/6 | Polyamide 6/6, Nylon 6/6 |

PEEK | Polyether Ether Ketone |

PVC | Polyvinyl Chloride (Shore D) |

| PARA | Polyaryl Amide |

PEI | Polyetherimide, Ultem |

PVDF | Polyvinylidene Fluoride |

| PBT | Polybutylene Terephthalate, Valox |

PES | Polyether Sulfone |

SAN | Styrene Acrylonitrile |

| PBT-PET | Polybutylene Terephthalate-Polyethylene Terephthalate |

PET | Polyethylene Terephthalate, Rynite |

TPO | Thermoplastic Polyolefin |

| PC | Polycarbonate |

PLA | Polylactic Acid |

TPU | Thermoplastic Polyurethane (Shore D) |

Elastomers and Synthetic Rubbers for Molding

| Elastomers and Rubber-Like Materials | |

| EPDM | Ethylene Propylene Diene Monomer Rubber, Viton |

TPE | Thermoplastic Elastomer, Santoprene |

| MPR | Melt Processable Rubber |

TPU | Thermoplastic Polyurethane (Shore A) |

| POE | Polyolefin Elastomer |

TPV | Thermoplastics Elastomer, Vulcanized Rubber |

| PVC | Polyvinyl Chloride (Shore A) |

LSR | Liquid Silicone Rubber |

Elastomers and Synthetic Rubbers for Molding

| Elastomers and Rubber-Like Materials | |

| EPDM | Ethylene Propylene Diene Monomer Rubber, Viton | TPE | Thermoplastic Elastomer, Santoprene |

| MPR | Melt Processable Rubber | TPU | Thermoplastic Polyurethane (Shore A) |

| POE | Polyolefin Elastomer | TPV | Thermoplastics Elastomer, Vulcanized Rubber |

| PVC | Polyvinyl Chloride (Shore A) | LSR | Liquid Silicone Rubber |

Custom Sourced Materials

If you do not see the material stock you are looking for, You can then submit your quote for manual for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required. Tiandiao can also use customer-sourced or customer-supplied resin for production projects.

Injection Molding Finishes

Standard Finish

Moldmaker's choice of finish. Typically SPI B-3 to D-3 depending on geometry and drafts. Interior, non-cosmetic faces, are typically as-machined.

SPI Finishes

Range of finishes from Grade 3 diamond / high polish to 320 stone low polish. Finishes include: SPI A-1 , SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3

MoldTech Finishes (Mold Texturing)

As Molded

No secondary polishing or grinding. Part will show tooling marks.

Threaded Inserts

We can install most commonly used standard inserts in UNF and metric sizes.

Pad Printing

Transfer a 2D image onto a 3D part. All images are subject to review.

Laser Engraving

Engrave part numbers, logos, and more onto your parts.

Assembly

Tiandiao has the ability to assemble and label molded parts. Discuss your needs with your salesperson.

Injection Molding Design Guidelines

| Feature |

Tip |

| Undercuts |

Reduce undercuts, which will increase the complexity and cost of the tool ejection mechanisms, by adding in pass-thru coring. |

| Wall Thickness |

Prevent wall sink and voids by maintaining an even wall thickness. Thinner walls reduce cycle time and reduce costs. |

| Drafts |

Ensure parts are designed with a minimum draft angle of 0.5°, or up to 5°, for faces with medium textures. |

| Ribs/Gussets |

Ribs should be 40-60% the thickness of outer walls and should still maintain draft. |

| Bosses |

Bosses should be designed at a depth of 30% the wall thickness and with a 30% edge groove. Attach them to side walls or ribs for structural integrity. |

Applications and Advantages of Injection Molding

|

|

|

| Rapid Prototyping Low-cost tooling allows molded parts to be produced in as fast as 10 business days at affordable prices. |

Production Parts Molding can be the ideal process for low-volume production molding of 250 units to mass production molding of over 1,000,000 units. Molded parts will generally perform better than the same part CNC machined or 3D printed using the same material. Careful selection of the resins allow for a wide range of properties and solvent compatibility. Molds are CNC machined to high precision, high tolerances and are able to produce thousands of identical parts with very small and intricate details. |

Range of Industries and Certifications We offer ISO 9001, AS9100, ISO 13485, UL, ITAR, and ISO 7 and 8 Medical Clean Room molding. |

Why Choose Tiandiao for DMLS 3D Printing?

|

|

|

Endless OptionsChoose from thousands of possible combinations of materials, finishes, tolerances, markings, and certifications for your order. |

Easy to UseGet your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. |

Guaranteed QualityWe conform with ISO 9001:2015 |

Keyword:

Injection Molding Service

Recommended Products

Leave a Message

Do You Have Any Intention To Cooperate?Please Leave Your Contact Information, And We Will Be Able To Contact You Immediately.