CNC turning services

Categories :

CNC Turning Overview

Tiandio has a network of over 5000 partner factories, including those with CNC lathes and turning centers, capable of meeting your project's capacity and capability needs while providing the most competitive pricing and lead times. Tiandio's machine learning technology platform also provides instant manufacturability feedback, ensuring your parts are optimized for CNC turning processes and meet your requirements. Our on-demand manufacturing platform can provide high-quality metal or plastic turned parts for rapid prototyping or low-to-high volume production. Get an instant quote from your 3D CAD file today.

Tiandio CNC Materials

| Materials | Available Types |

| Aluminum | 5052 Aluminum, 7075 Aluminum, 7075-T6 Aluminum, 6063-T5 Aluminum, 7050-T7451 Aluminum, MIC-6 Aluminum, 6061-T6 Aluminum, 2024-T3 Aluminum |

| Brass/Bronze | C360 Brass, 260 Brass, C932 M07 Bearing Bronze |

| Copper | EPT Copper C110, 101 Copper |

| Plastic | ABS, Acetal [Delrin], Acrylic, G-10 Fiberglass Cloth Laminate, 6/6 Nylon, PEEK, Polycarbonate, PTFE [Teflon], Polypropylene, Ultra-High Molecular Weight Polyethylene |

| Steel | 4130 Alloy Steel, 4140 Alloy Steel, ASTM A36, 15-5 Stainless Steel, 17-4 Stainless Steel, 18-8 Stainless Steel, 303 Stainless Steel, 304 Stainless Steel, 316/316L Stainless Steel, 416 Stainless Steel, 420 Stainless Steel, 1018 Steel, A36 Steel |

| Titanium | Grade 2 Titanium, 6Al-4V Titanium |

| Zinc | 500 Zinc Alloy Sheet |

Custom Sourcing Materials

Get instant quotes for various CNC turned metal and plastic parts. If you can't find your required material in stock, submit your quote request after specifying your functionality, tolerances, inspection requirements, and required quantity for review by our expert engineers.

As-Milled

Fastest turnaround surface finish options. Parts will retain visible machine marks, and may have sharp edges and burrs, which can be removed upon request. Surface finish is equivalent to 125 uin Ra.

Shot Peening

Parts will have a smooth matte finish.

Anodizing (Type II or III)

Type II creates a corrosion-resistant surface. Parts can be anodized in various colors—clear, black, red, and gold are most common—typically associated with aluminum. Type III is thicker and, in addition to the corrosion resistance of Type II, provides a wear-resistant layer.

Powder Coating

This is a process where powder coating is sprayed onto the parts and then baked in an oven. This creates a strong, wear-resistant and corrosion-resistant layer that is more durable than standard paint methods. A variety of colors are available to create the desired aesthetic.

Custom

Can't find the surface finish you need? Submit an RFQ and we will find the right surface finish process for you.

Applications of CNC Turning

|

|

|

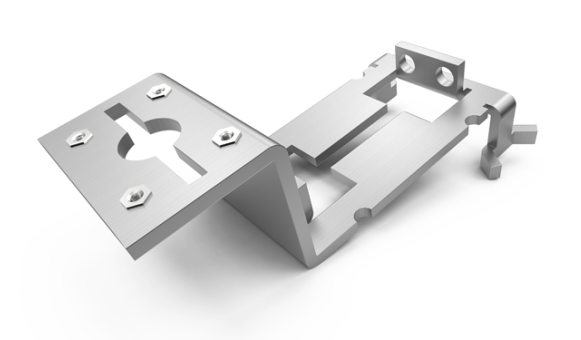

Rapid ToolingBecause CNC turning can be applied to almost any material, it is well-suited for rapid tooling, i.e., the manufacturing of jigs or molds. |

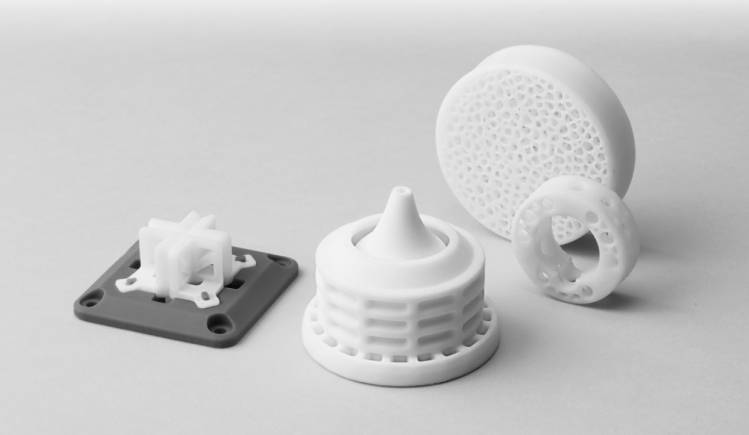

Rapid PrototypingThe wide range of available materials, low unit cost, and fast production speed make CNC turning an ideal choice for prototyping. |

High-Volume ProductionHigh-quality surface finishes, a wide selection of materials, and precise tolerances make CNC lathe turning an ideal technology for producing parts in high volumes. |

Advantages of CNC Turning

Fast Turnaround

Tiandio uses the latest CNC machines to produce high-precision, fast-turnaround parts, with the fastest turnaround time being 1 day.

Custom Surface Finishes

Choose from a variety of surface finishes for metal and plastic parts, manufactured to exact design specifications.

Material Selection

Choose from over 50 metal and plastic materials. CNC machining offers a variety of certified materials.

Precision

High-precision tolerances are offered, ranging from +/-0.0254mm to +/-0.127mm, depending on customer specifications.

Scalability

CNC machining is well-suited for producing 1-10,000 parts.

CNC General Tolerances

| Description | General Tolerances |

| Dimensional Tolerances | +/- 0.127mm for dimensional features (length, width, height, diameter) and location (position, concentricity, symmetry). |

| Orientation and Form Dimensions | 0-12mm +/- 0.005mm, angle 1/2 degree. For 24mm and above, please consult Tiandio's manufacturing standards. |

| Edge Condition | By default, sharp edges will be deburred and chamfered. Critical edges that must remain sharp should be noted and specified on the drawings. |

Overview: What is CNC turning?

Fundamentals of CNC Lathes

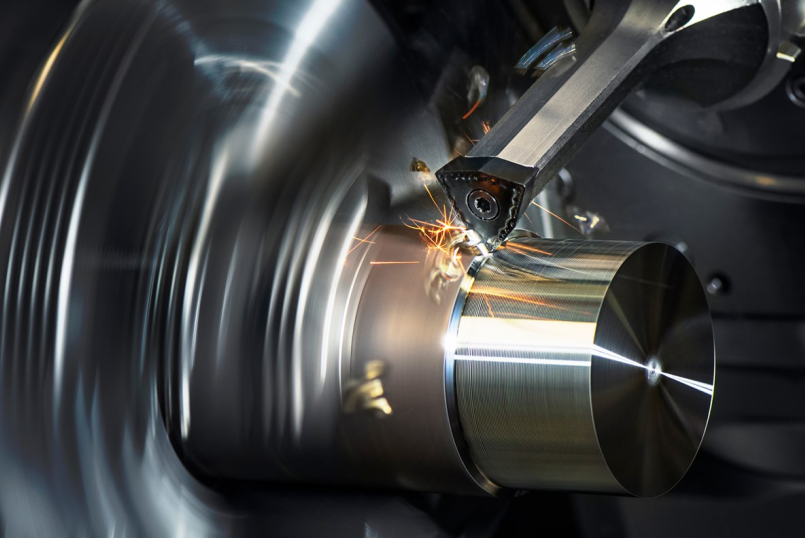

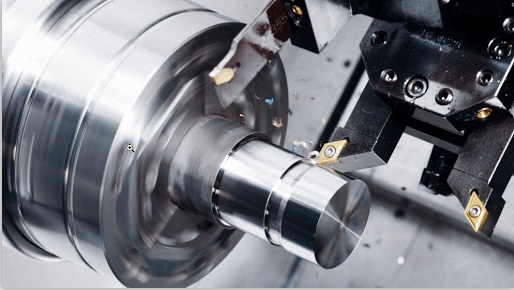

CNC lathes, also known as powered turret lathes, are ideal for cutting any symmetrical cylindrical or spherical parts. Typically, the lathe rotates the workpiece on a vertical or horizontal axis, while a stationary forming tool moves around the workpiece along a more or less linear path. The action of cutting a workpiece on a CNC lathe is called turning.

How CNC Turning Works

CNC lathes use a subtractive method to create the desired shape. A raw bar stock is loaded into the lathe's spindle chuck. The chuck holds the workpiece as the spindle rotates. Once the spindle reaches speed, a stationary cutting tool removes material until the desired geometry is achieved.

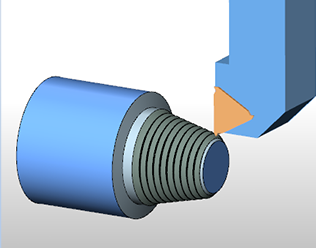

Lathes with powered tool turrets can perform many operations, including facing, threading, knurling, drilling, boring, reaming, and taper turning. Different operations require tool changes, which increases cost and setup time.

After all machining is complete, the part is cut from the bar stock and post-processed. The CNC lathe can then repeat the operation with minimal setup time.

Types of CNC Lathes

Many types of lathes exist, but the most common are 2-axis CNC lathes and Swiss-type lathes. Swiss-type lathes are unique because they feed the bar stock through a guide bushing, allowing the cutting tool to cut closer to the support point. This makes them ideal for machining slender parts and micro-machining. Some Swiss-type lathes have a second tool head that functions similarly to a CNC milling machine, allowing multiple operations to be performed without re-positioning the workpiece. This makes Swiss-type lathes very cost-effective for complex turned parts.

Advantages of CNC Turning

Like CNC milling machines, CNC lathes are easy to set up and highly repeatable, making them suitable for rapid prototyping and low to high volume production. Multi-axis CNC turning centers and lathes allow for multiple machining operations on a single machine, providing a cost-effective solution for complex geometries that would otherwise require multiple machines or tool changes on a traditional CNC milling machine.

Keyword:

CNC turning services

Recommended Products

Leave a Message

Do You Have Any Intention To Cooperate?Please Leave Your Contact Information, And We Will Be Able To Contact You Immediately.