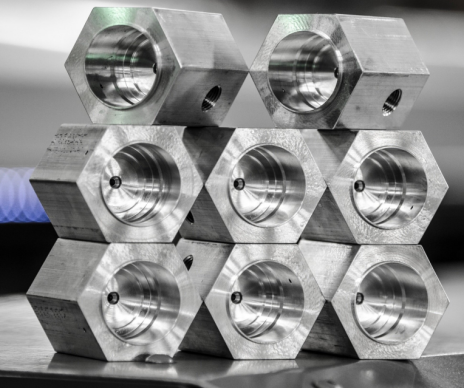

CNC Milling Services

Categories :

High-quality, rapid CNC milling

Tiandio is a qualified manufacturing factory. We support 3-axis, 4-axis, and 5-axis milling, as well as right-angle milling capabilities, helping you quickly create designs, from simple straight lines to complex geometries. Tiandio provides instant quotes, on-demand delivery times, and design manufacturability feedback on materials and manufacturing processes, providing services for your customized CNC milled parts regardless of your industry. Get your quote today.

CNC Machining Materials

Materials offered by Tiandio

Custom-procured materials

A variety of CNC machined metal and plastic parts are available for immediate quotes. If you don't find the material stock you need, please send us your quote after specifying your functionality, tolerances, inspection requirements, and required quantity for professional engineering review.

Available Surface Finishes

As-milled

Fastest turnaround surface finish option. Parts will have visible tool marks on the surface, and may have sharp edges and burrs, which can be removed upon request. Surface roughness is equivalent to 125 uin Ra.

Shot Peening

Parts will have a smooth, matte finish.

Anodizing (Type II or III)

Type II produces a corrosion-resistant finish. Parts can be anodized in various colors—clear, black, red, and gold are most common—typically associated with aluminum. Type III is thicker and, in addition to the corrosion resistance of Type II, provides a wear-resistant layer.

Powder Coating

This is a process where powder coating is sprayed onto the part and then baked in an oven. This produces a tough, wear-resistant, and corrosion-resistant layer that is more durable than standard paint methods. Various colors are available to create the desired aesthetic.

Custom

Can't find the surface finish you need? Submit an RFQ and we will find the right surface finish process for you.

| Aluminum | Bronze/Brass | Copper | Plastic | Steel/Titanium/Zinc |

| 5052 Aluminum | C360 Brass | EPT Copper C110 | ABS | 4130, 4140 Alloy Steel |

| 7075 and 7075-T6 Aluminum | 260 Brass | 101 Copper | Acetal [Delrin] | ASTM A36 |

| 6063-T5 Aluminum | C932 M07 Bearing Bronze | Acrylic | 15-5, 17-4 Stainless Steel 18-8, 303 |

|

| 7050-T7451 Aluminum | G-10 Garolite | 303, 304 Stainless Steel 316/316L |

||

| MIC-6 Aluminum | 6/6 Nylon | 416, 420 Stainless Steel | ||

| 6061-T6 Aluminum | PEEK | Mild Steel | ||

| 2024-T3 Aluminum | Polycarbonate | A36 Steel | ||

| PTFE [Teflon] | Grade 2 Titanium 6Al-4V Titanium 500 Zinc Alloy Sheet |

|||

| Polypropylene | ||||

| Ultra-High Molecular Weight Polyethylene |

Applications of CNC Milling

DMLS materials offered by Tiandio:

|

|

|

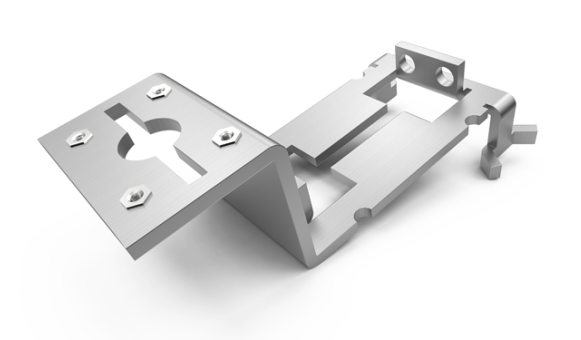

Rapid ToolingBecause CNC can be applied to almost any material, it is well-suited for rapid tooling, i.e., creating jigs or molds. |

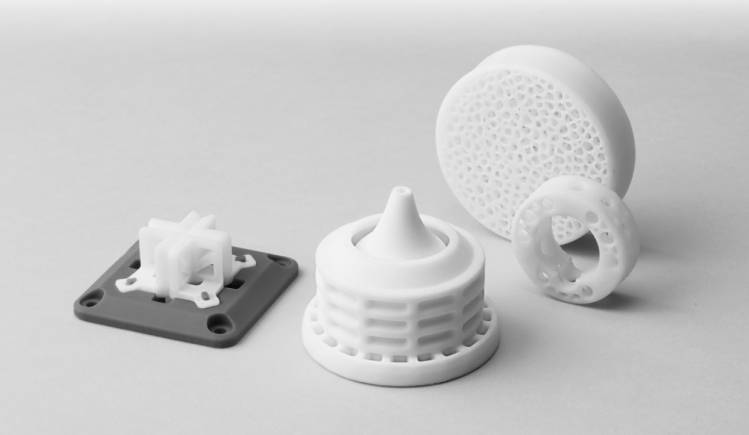

Rapid PrototypingA wide variety of materials, low unit cost, and production speed make CNC ideal for prototyping. |

End-Use ProductionHigh-quality surface finishes, a wide selection of materials, and precise tolerances make CNC an ideal technology for end-use parts. |

Advantages of CNC Milling

|

|

|

|

Fast TurnaroundTiandio uses the latest CNC machines to produce high-precision, fast-turnaround parts, with the fastest turnaround time being as fast as 1 day. We also provide instant quotes for CNC machined parts, thereby shortening your RFQ process time. |

High-Precision TolerancesHigh-precision tolerances are offered, ranging from +/-0.0254mm to 0.127mm, depending on customer specifications. We are experts in manufacturing truly custom and ready-to-use parts. |

ScalabilityCNC machining is well-suited for prototyping and production parts. Tiandio's large-scale production capabilities can help you scale from the testing phase to producing 100,000 parts or more. |

Material SelectionChoose from over 50 metal and plastic materials. CNC machining offers a variety of certified materials. |

CNC General Tolerances

| Description | General Tolerances |

| Distance Dimensions | For features where dimensions (length, width, height, diameter) and location (position, concentricity, symmetry) are within +/-0.127mm. |

| Orientation and Form Dimensions | 0-304.8mm +/-0.127mm, angle 1/2 degree. For dimensions 609.6mm and above, please refer to the Tian Diao manufacturing standard. Over 609.6mm, please refer to the Tian Diao manufacturing standard. |

| Edge Condition | By default, sharp edges will be chamfered and deburred. Critical edges that must remain sharp should be noted and specified on the drawings. |

|

Overview: What is CNC Milling? How CNC Milling Works Milling machines can be used to contour cut softer materials, but are not as cost-effective for this purpose as CNC routers. The main difference is that with a CNC router, the workpiece remains stationary while the router cutting head moves around the workpiece, whereas a CNC milling machine can move both the cutter and the workpiece simultaneously. CNC milling machines are primarily used in industrial manufacturing, while CNC routers are more common in low-volume manufacturing (such as woodworking). |

Types of CNC Milling Machines

3-Axis

The most widely used type of CNC milling machine. Using X, Y, and Z axes enables the 3-axis CNC milling machine to handle a variety of jobs.

4-Axis

This type of router allows the machine to rotate around a vertical axis, moving the workpiece for more continuous processing.

5-Axis

These machines have three traditional axes and two additional rotary axes. Therefore, a 5-axis CNC router can machine 5 sides of a workpiece in one setup without removing and resetting. The workpiece rotates, and the spindle can also move around the workpiece. These machines are larger and more expensive.

Other Advantages of CNC Milling

CNC milling machines are designed for precision manufacturing and repeatability, making them ideal for rapid prototyping and low- to high-volume production runs. CNC milling machines can also use a variety of materials, from basic aluminum and plastics to more exotic materials such as titanium, making them suitable for almost any job.

Why Choose Tian Diao for CNC Milling?

|

|

|

Unlimited ChoicesChoose from thousands of possible combinations of materials, surface finishes, tolerances, markings, and certifications for your order. |

Easy to UseGet your parts delivered right to your doorstep without the hassle of sourcing, project management, logistics, or shipping. |

Guaranteed QualityWe are ISO 9001:2015 compliant |

Keyword:

CNC Milling Services

Recommended Products

Leave a Message

Do You Have Any Intention To Cooperate?Please Leave Your Contact Information, And We Will Be Able To Contact You Immediately.